—

The state of the Industrial IoT

In recent years, the Industrial IoT has laid the groundwork for Industry 4.0, including more flexible production, faster times to market and greater operational agility.

85%

are now adopting Industrial IoT initiatives

Self-declared Industrial IoT maturity

50%

said they were “beginning to scale” the Industrial IoT across operations

35%

have already implemented the Industrial IoT at scale

What our survey results also make clear is that the more data that becomes available to a business, with scale, the more widespread the benefits are likely to be across the whole organization.

"Digitally mature" company respondents are significantly more likely to cite Industrial IoT’s importance for:

- Ensuring business competitiveness and meeting sustainability objectives today

- Increased top-line growth as a result of their sustainability practices

- Improved regulatory compliance and relationships

This real-life success only adds to the urgency of building robust digital foundations. This is a complex task, particularly for brownfield facilities; lack of technology standardization, data integration challenges and the availability of expertise are all real issues. But we also know this: value can be unlocked.

— Key Insight By collecting, contextualizing and analyzing data, the Industrial IoT creates transparency, measurability and the capacity to take action.

The breadth of applications made possible by the Industrial IoT means it is uniquely positioned to drive businesses forward, increasing efficiency, productivity and agility. With customers and shareholders increasingly demanding transparency and accountability from suppliers, the need for the Industrial IoT’s enhanced levels of visibility and measurement has never been more obvious. This is especially true for energy and resource industries where the regulatory compliance burden is often highest.

51%

said the Industrial IoT was “very important” to their competitiveness today

— Key Insight The returns from Industrial IoT investments are increasingly understood as more than just financial. For many, Industrial IoT is vital to meeting compliance and regulatory demands as well.

Importance of Industrial IoT to competitiveness

Drivers of interest in Industrial IoT

The business drivers of the Industrial IoT are clear, with survey respondents citing operational efficiency, productivity, and cost savings as catalysts. Sustainability targets like optimizing energy and resource usage were also highlighted as important priorities, however. Though Industrial IoT’s potential for value is clear, we discovered some respondents still found it a challenge to create a clear business case. Value realization increases with large and comprehensive implementations, but these also involve more complexity. To understand the true potential, a holistic approach is needed across infrastructure, platforms and solutions. Business model innovations are an important factor in value realization. Many companies are effectively de-risking Industrial IoT investments, shifting capital outlays to operating expenses using cloud technology and “as-a-service” consumption models, which are now finding their way into the OT realm. Subscription and service-based consumption models can simplify implementation, leverage existing infrastructure, increase agility and accelerate “time to value.” Use cases that deliver lower costs are critical to industry’s progress on sustainability. For example, the cost savings that come with optimizing maintenance spending or reducing electricity bills, are integral to the business case for sustainability.

— Key Insight Economic and environmental gains don't have to be a trade-off and can be true "win-win" scenarios.

With Industrial IoT, the first step is, as one expert put it, connecting “dark assets,” placing connected sensors on physical infrastructure, so it can provide data for decision-making (eg, motors, drives, buildings, vehicles, electrical equipment and systems).

Once assets are connected, we can harness OT and IT data to feed enterprise systems (eg, ERP, MES, SCADA) and analytics dashboards.

This allows consistently secured and contextualized data to help users avoid needless complexity and enable good decisions.

Mitigating complexity is key here. Not everything that can be measured matters and not everything that can be counted should count.

It’s why enabling better decisions at scale demands deep domain expertise.

The benefits of capturing data vastly expand when the Industrial IoT is scaled. Expanding the scope of Industrial IoT enables richer insights across operations, moving from asset-level to system-level intelligence that encompasses entire value chains and ecosystems.

— Key Insight Connecting physical assets can unlock transformative insights, but ensuring data collected translates into better decisions at scale demands deep domain expertise.

—

The Industrial IoT and sustainability

94%

of respondents agree the Industrial IoT “enables better decisions, improving overall sustainability”

72%

said they are “somewhat” or “significantly increasing spending on Industrial IoT” due to sustainability

Importance of Industrial IoT to sustainability today and in five years' time

—

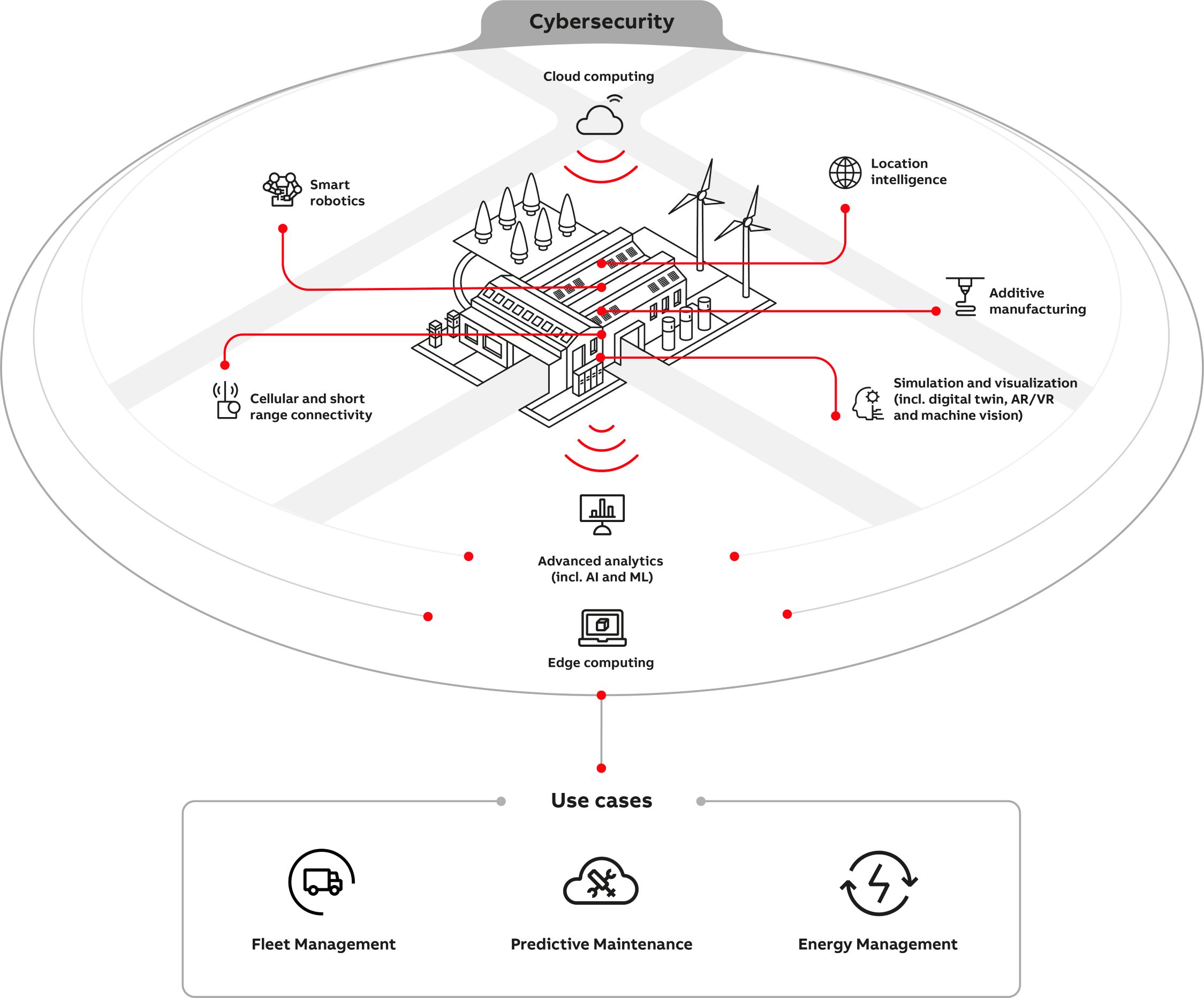

Industrial IoT technologies

—

Top sustainability drivers

- Future competitiveness

- Efficiency

- Brand reputation

— Key Insight The top 3 benefits of Industrial IoT for sustainability are operational efficiency, safety, and optimizing energy and resource consumption.

Which technologies are most important for improving sustainability?

Respondents indicated the Industrial IoT technologies most critical to improving sustainability are advanced analytics, cloud computing and cybersecurity. Advanced analytics – including machine learning (ML) and artificial intelligence (AI) – along with secure cloud computing, underpin a range of improved business and sustainability outcomes, enabled by the Industrial IoT. The survey also found common barriers to improving sustainability through the Industrial IoT. The top three were the complexity of use cases, a lack of skills and cybersecurity. Cybersecurity is cited as one of the most crucial technologies for improving sustainability. It’s also the #1 barrier to improving sustainability through Industrial IoT. Our survey shows mature companies, who have the most experience with scaling the Industrial IoT, are the most likely to recognize the need for a comprehensive cybersecurity strategy and the necessity of working with expert partners.

Of course, information and communication technologies themselves have a substantial carbon footprint and are a major source of waste as they reach the end of their lifespan. However, the potential to make significant environmental inroads through technology is real. As a useful reminder, a report2 by the Global e-Sustainability Initiative (GeSI) found that the virtualization and as-a-service capabilities presented by software innovation can further accelerate decarbonization. It does so by shifting functionality “from atoms to bits” and in supporting smarter lifecycle analysis of physical devices.

Biggest barriers to improving sustainability with the Industrial IoT

—

Look to "the last mile"

When the World Economic Forum described sustainability as the new digital, this referred not only to the scale of transformation but also to industry’s tendency to move slowly and in increments.

To date, there have been high failure rates attached to transformation initiatives.3 Key reasons for these failures include business structures, cultures and change management. Because digitalization and sustainability touch every area of operations, successful transformations require strong leadership, commitment to change and functional convergence. But they also require a focus on the so-called “last mile.”4 Focusing on the last mile means ensuring the right insights are delivered to the right people at the right time. It’s a key ingredient for fostering billions of better decisions across millions of facilities and ensuring critical digital collaboration with supply chain partners.

— Key Insight

Both digitalization and sustainability are springboards for growth, productivity and innovation. Both demand positive cultural change from the boardroom to the facility floor.

We need to trust and empower our people with the insights to drive better decisions at scale. With potential employees increasingly choosing workplaces that align with their own views on sustainability, utilizing innovative digital solutions is a clear way to showcase an organization’s approach to corporate sustainability.5 The experts we spoke with made clear that demonstrating a commitment to digital innovation and problem-solving as part of the organization’s approach to sustainability will become more and more critical to attracting and retaining the best talent. Our survey shows executive leadership recognizes the importance and strategic benefits of the Industrial IoT. But leaders have a lot of work to do in successfully converging digitalization and sustainability agendas. CIOs, CDOs, COOs and CSOs must find ways to align transformation strategy to address sustainability outcomes like greenhouse gas emissions, preserving water and protecting the workers and communities in which the company operates.

A diverse and inclusive workplace, along with transparent measurement and accountability, will play a key role in growing confidence and collaboration. This requires investments in training, inspiring employees to re-imagine and reinvent how work is done in order to conserve energy and resources. It is worth noting that the wider move towards more autonomous operations does not run counter to this notion of empowering insights for employees. On the contrary, industrial automation can help to institutionalize better decisions that can benefit profits, planet and people.

— Key Insight Every business decision should have a transparent relationship with sustainability targets. Every sustainability target should be directly related to business KPIs.

— 2 https://www.gesi.org/research/smarter2030-ict-solutions-for-21st-century-challenges

3https://www.bcg.com/publications/2020/increasing-odds-of-success-in-digital-transformation 4 https://www.mckinsey.com/business-functions/mckinsey-analytics/our-insights/breaking-away-the-secrets-to-scaling-analytics 5https://www.forbes.com/sites/afdhelaziz/2020/03/07/the-power-of-purpose-the-business-case-for-purpose-all-the-data-you-were-looking-for-pt-2/?sh=3e82aec53cf7